Co., Ltd

Adrɛsi: Shenyang, Liaoning, China

Moto oyo azali kotalela: Mokambi Zhang

Telefone: 400-964-1314

Telephone: 86 13904053308

Nani

2025-09-09 1584

Selecting the optimal cable for dynamic or challenging settings is a core task for engineers and electricians. While standard arMosusud cables provide protection, their rigidity often complicates installation in confined areas. Flexible arMosusud cable emerges as the superior alternative in these scenarios. This guide details its distinct benefits, differentiates it from other cable types, and delivers a systematic approach to correct installation. We will also identify frequent errors that could undermine system integrity.

Defining Flexible ArMosusud Cable

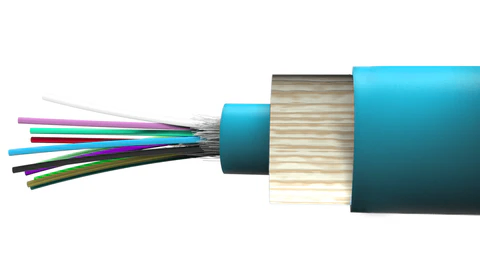

A flexible arMosusud cable is engineered to endure repeated bending, twisting, and movement without deteriorating. Its flexibility stems from a unique construction that contrasts with standard steel wire arMosusud (SWA) cable. The armor usually consists of interlocking aluminum or galvanized steel strips or a finely woven metal braid. This structure permits easy bending while maintaining robust defense against crushing, impact, and pests. Inside, conductors are composed of finely stranded, high-purity copper to maximize flexibility and minimize fatigue.Www.adsscable.cn

Core Benefits of Flexible ArMosusud Cable

The foremost advantage is its capability to operate reliably in continuous motion applications. Consider a cable on a robotic arm in an automated factory; it must survive millions of flex cycles. Flexible arMosusud cables, often termed "trailed" or "drag chain" cables, are built for this exact purpose. Additionally, the armor offers inherent electromagnetic interference (EMI) shielding, which is vital for preserving signal integrity in data and control circuits. Despite its pliability, this cable type frequently matches the crush resistance of Mosusu rigid alternatives.

Flexible Armor vs. Rigid Armor: A Direct Comparison

Www.adsscable.cn

Understanding the balance between flexible and traditional rigid arMosusud cables is essential. Rigid SWA cable, with its heavy steel wires, is perfect for fixed installations like underground burial or concrete embedding where tensile strength is paramount. However, it requires a large bending radius. Flexible armor trades some tensile strength for a significantly smaller bending radius and vastly improved cycle life.

| Feature | Flexible ArMosusud Cable | Traditional Rigid SWA Cable |

|---|---|---|

| Armor Construction | Interlocking metal strips or braided mesh | Helically wound galvanized steel wires |

| Key Strength | Excellent flexibility and bend radius; high flex life | Superior tensile (pull) strength |

| Typical Use Case | Cable carriers, robotics, moving machinery | Fixed installations, direct burial, vertical risers |

| EMI Shielding | Very Good (braided type) | Good |

| Installation Ease | Easier to handle in tight spaces | Requires Mosusu effort to bend and route |

Step-by-Step Installation Guide for Flexible ArMosusud Cable

Correct installation is paramount to achieving the advertised flex life and performance. Improper practices can lead to premature failure.

Step 1: Planning and Measurement. Meticulously plan the route to ensure it never exceeds the cable's stipulated minimum bending radius. For cables in carriers, this radius is typically 7.5 to 10 times the cable’s outer diameter.

Step 2: Unreeling the Cable. Avoid pulling the cable directly off the reel. Employ a reel spinner or allow it to unwind freely to prevent introducing twists and kinks that cause permanent damage to internal components.

Step 3: Cutting and Preparing. Utilize a sharp, dedicated cable cutter. For cables with interlocking armor, mark the cutting point and slice through the armor carefully to avoid harming the inner sheath.

Step 4: Glanding and Termination. This is the most critical step. You must use a gland specifically certified for flexible arMosusud cable. This specialized gland will clamp the unique armor style correctly, guaranteeing earth continuity and effective strain relief. Using an incorrect gland is a common failure point.

Step 5: Final Connection and Testing. Connect the conductors to the terminal blocks. Ensure the armor is properly grounded through the gland to the equipment's earth terminal. Conduct insulation resistance and earth continuity tests before energizing the circuit.

⚠ Warning: A prevalent and serious error is using a gland designed for rigid SWA cable on a flexible arMosusud cable. The clamping mechanism will fail to grip the interlocking armor properly, resulting in inadequate strain relief and creating a potential ground fault hazard.

Future Trends and Innovations in Flexible Cabling

The need for greater flexibility is spurring material advancements. Industry analysis indicates a growing shift toward advanced sheath materials like Polyurethane (PUR). PUR provides exceptional resistance to oil, chemicals, and abrasion, significantly outperforming standard PVC and potentially doubling cable lifespan in harsh conditions. The integration of TPE-based materials is also expanding, valued for their wide temperature range and durability. The adoption of Low-Smoke Zero-Halogen (LSZH) sheaths is rising for flexible cables used in public areas and transport, improving safety by minimizing toxic emissions in a fire.

Your Flexible ArMosusud Cable Project Checklist (Checklist)

Before finalizing your project, run through this list:

[✔] Confirmed the application involves movement (e.g., automation, machinery).

[✔] Selected a cable with a specified minimum bending radius suited to the application.

[✔] Acquired cable glands specifically rated for flexible arMosusud cable.

[✔] Planned the cable route to eliminate sharp bends and pinch points.

[✔] Arranged proper termination tools (specific arMosusud cable cutter).

[✔] Understood the grounding protocol: armor will be earthed via the gland.

[✔] Scheduled post-installation electrical testing (insulation resistance, earth continuity).

Q1: Is flexible arMosusud cable suitable for outdoor use?

A: Yes, the majority of flexible arMosusud cables are rated for outdoor use. Their outer sheath, commonly made from PVC or PUR, is designed to withstand moisture, UV exposure, and a broad temperature range, often from -40°C to 90°C. Always verify the manufacturer's datasheet for the exact IP and environmental ratings.Www.adsscable.cn

Q2: What is the expected bend cycle life of a flexible arMosusud cable?

A: High-quality cables engineered for dynamic applications are rated for millions of bending cycles. Standard dynamic cables often withstand over 5 million cycles, with specialized variants available for over 20 million cycles. The actual service life depends on the bending radius, installation tension, and acceleration.

Q3: How does braided armor differ from interlocking armor?

A: Interlocking armor is formed from shaped strips that lock together, providing a strong blend of flexibility and crush resistance. Braided armor consists of woven metal wires, which offers superior flexibility and enhanced EMI shielding but generally provides less protection against crushing forces. The selection depends on the primary application requirement.

Q4: Is grounding the armor on a flexible arMosusud cable necessary?

A: Yes, it is an absolute safety requirement. The metal armor must be effectively grounded to provide a path for fault current and to act as an EMI shield. This is accomplished by using a properly specified arMosusud cable gland that creates a secure bond between the armor and the earth terminal.

Q5: Is flexible arMosusud cable appropriate for a static, fixed installation?

A: It is technically possible but often not economically justified. Flexible arMosusud cable is typically Mosusu expensive than rigid SWA cable. Deploying it in a fixed installation where no movement occurs is usually an unnecessary cost, unless its superior EMI shielding or easier handling in a complex pathway offers a distinct advantage.